Basic Knowledges

The reason sake rice is polished

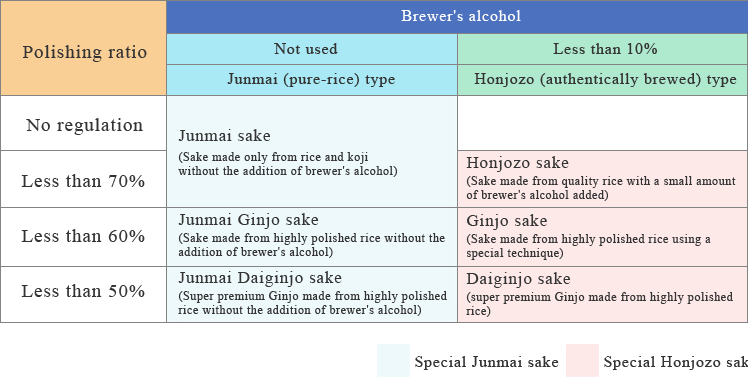

Polishing ratio of sake-brewing rice

In sake brewing, we use the expression “polishing rice” instead of “scraping rice.”

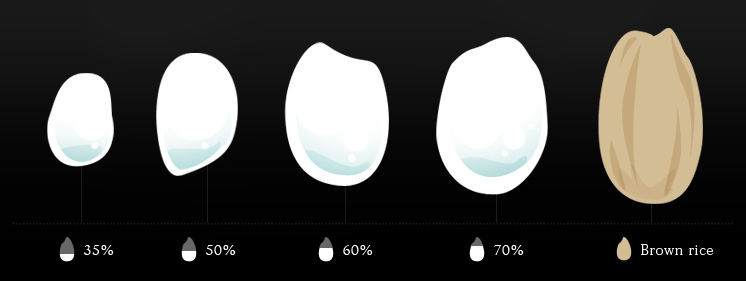

The rice-polishing ratio shows how much of the rice surface is removed. For instance, when the ratio is 60%, 40% of the brown rice surface is polished away.

The reason for polishing has a significant connection to the composition of rice itself.

The core of the rice grain is rich in starch, while fats, vitamins and proteins are concentrated near the surface.

The fat and protein near the surface of normal rice for eating is nutritious, so the rice-polishing rate is around 90%.

On the other hand fat and protein have strong flavor profiles that, in excess, can adversely affect the flavors and aromas of sake, resulting in an unpleasant product. This is why rice-polishing is a vital step for making sake.

Sake made with unpolished rice has a comparatively deeper, thicker taste, giving the impression of a strongly flavored sake with a noticeable smell of rice.

But when sake is made using well-polished rice, the aroma is bright, with a flavor that leaves a light, clear impression.

This is the reason why many junmai ginjoshu and junmai daiginjoshu, with rice-polishing rates of 50-60%, have such a clear and brilliant taste.